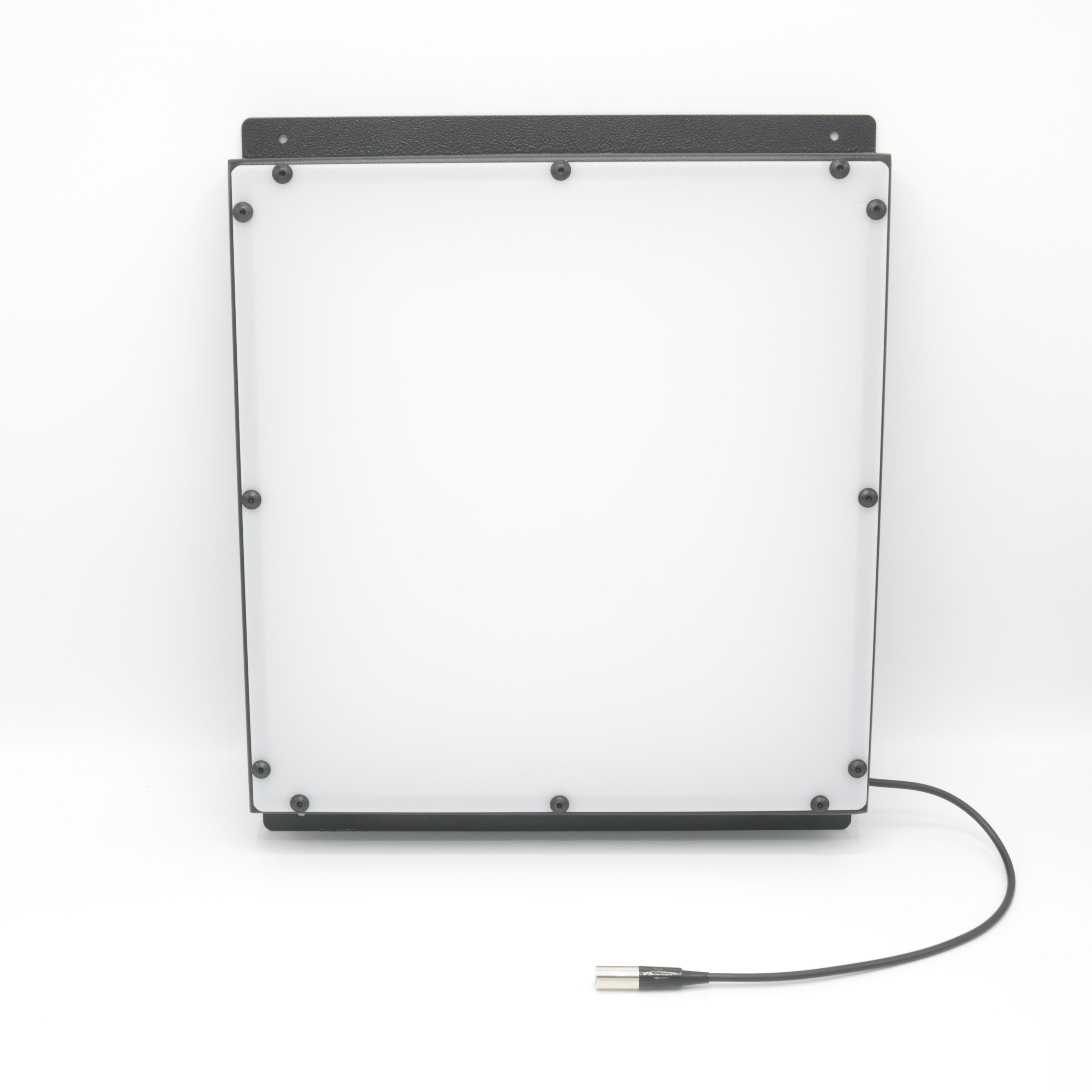

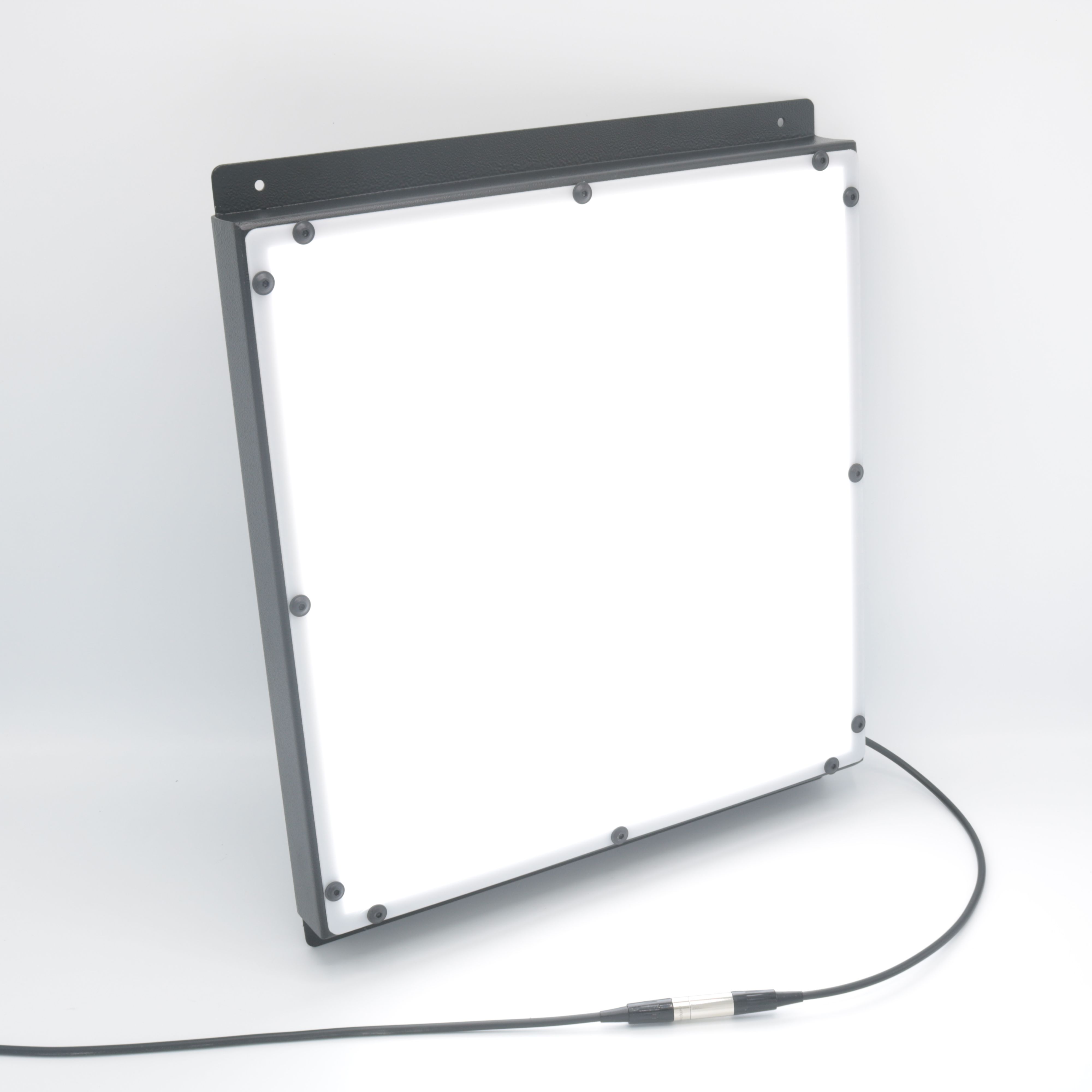

Collimated Backlight C3030

LUDRE COLLIMATED BACKLIGHT D3030 MACHINE VISION IMAGE PROCESSING LIGHT

TECHNICAL SPECIFICATIONS

Illumination Color: 6500K

Illumination Angle: 85°

Illumination Intensity: 2.56 k lm

Number of LEDs: 1044

Input Voltage: 24 V

Input Current (15 µs): 13,7 A

Input Current (1 second): 8,8 A

Input Current (1 minute): 7,1 A

Input Current (continuous): 5,5 A

Dimensions: 34 cm x 30 cm x 5 cm

Stable Operation at Fixed Voltage: Yes

Diffuser Option: Yes

PRION COLLIMATED BACKLIGHT MACHINE VISION IMAGE PROCESSING LIGHT

Collimated backlight is a specialized type of backlighting used in industrial image processing and computer vision applications. The term "collimated" refers to the arrangement of light rays into a parallel beam. This type of lighting allows light to travel in a specific direction without scattering, making it ideal for applications requiring precise measurement and detection.

In traditional backlight systems, light disperses in all directions, whereas collimated backlight directs light in a narrow, parallel beam. This feature enables light to pass only through the edges of the object, minimizing shadowing and creating a sharp silhouette. As a result, the dimensions, edge geometry, and surface features of the object can be detected with much higher accuracy.

Advantages of Collimated Backlight:

- High Precision: The parallel nature of the light beam increases accuracy in measurement applications.

- Sharp Edge Detection: The edges of objects are defined with exceptional clarity, which is particularly beneficial for objects with fine details.

- Reduced Reflection and Glare: Collimated light minimizes reflections and glare, resulting in clearer images.

- High-Quality Data for Algorithms: Provides superior data quality for deep learning and image processing algorithms.

.png)

| Application | |

| Engine Part Inspections | Material Strain Measurement |

| Packaging Inspections | Motion Detection |

| Medical Bottle Inspections | Product Counting |

| Food Package Inspections | Color Concentration Information |

| Surface Inspections | Coordinate Information |

| Microscopic Camera Applications | Particle Identification |

| Particle Imaging in Liquid | Cell Imaging |

| Particle Size Measurement | Machine Monitoring |

| Particle Counting | Image Processing |

| Machine Vision | Industrial Led Lighting |

| Cell Identification | Conveyor Line Lighting |

| Flame Length Measurement | Robot Vision Applications |

| Edge Detection | Industry 4.0 Applications |

.png)

|

Key Advantages |

|

|

Optional Collimation Filter |

Pulse and Continuous Operation Options |

|

Easy-to-Mount Design |

Homogeneous Light Distribution |

|

Various Color Options |

Low Power Consumption |

|

Long Lifespan and Durability |

Adaptability to High-Speed Processes |

.png)

.png)