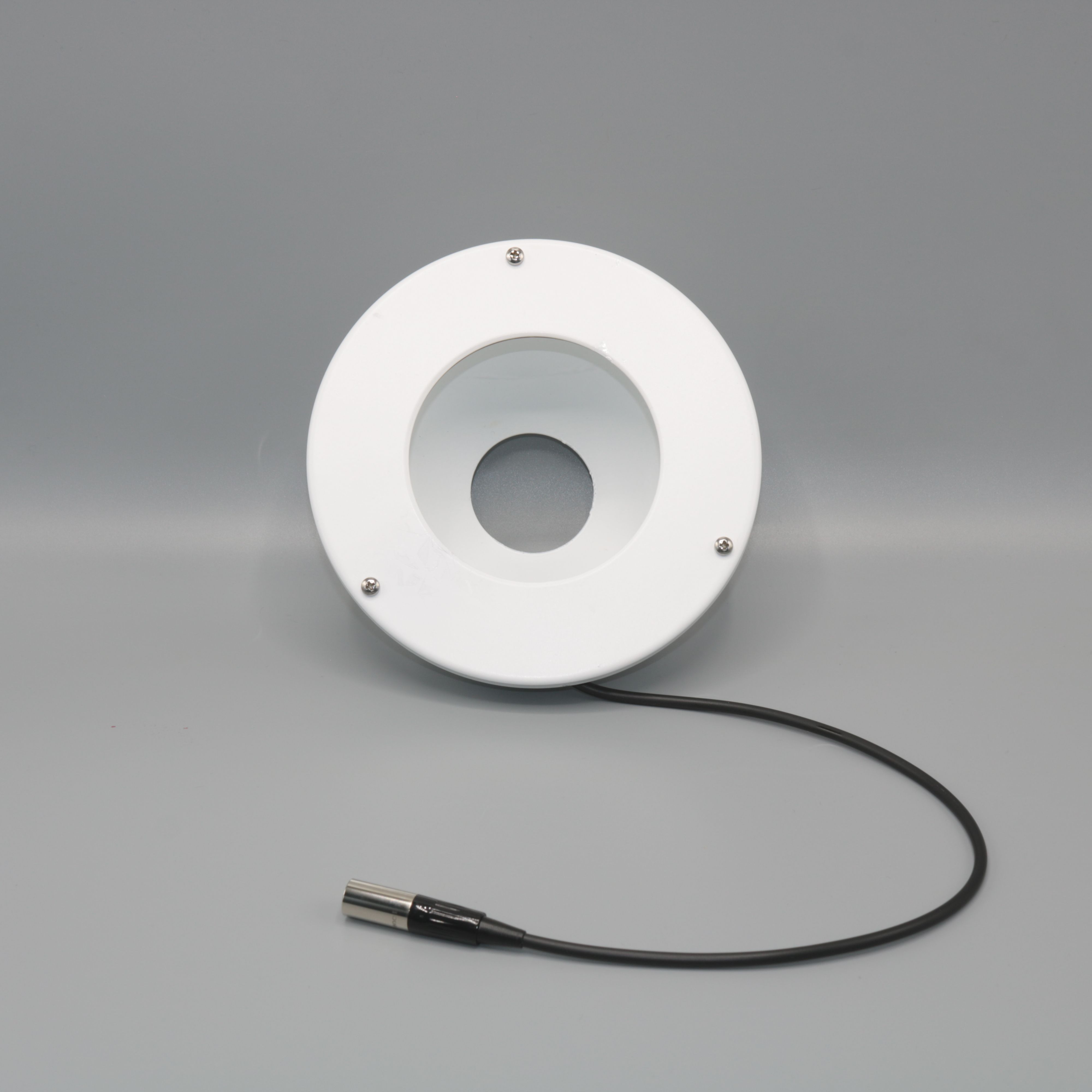

Dome Light DM12

Dome Light DM12 MACHINE VISION IMAGE PROCESSING LIGHT

TECHNICAL SPECIFICATIONS

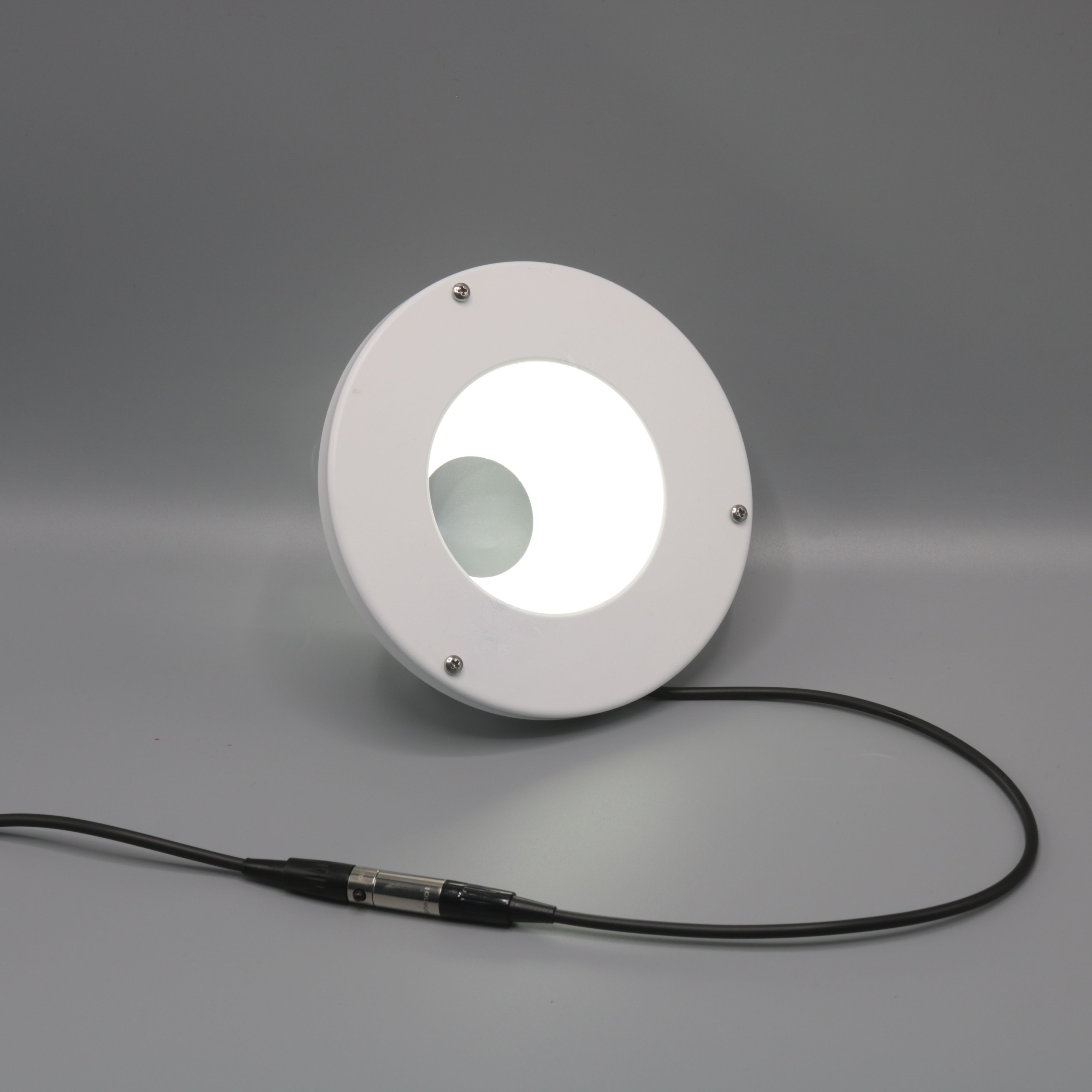

Lighting Color: 6500K,

Lighting Angle:85°

Intensity Of Illumination: 2,56 k lm

Number of Leds: 200

Input Voltage: 24 V

Input Current (15 µs): 1,4 A

Input Current ( 1 second): 1 A

Input Current (1 minute): 0,8A

Input Current (continuous): 0,4 A

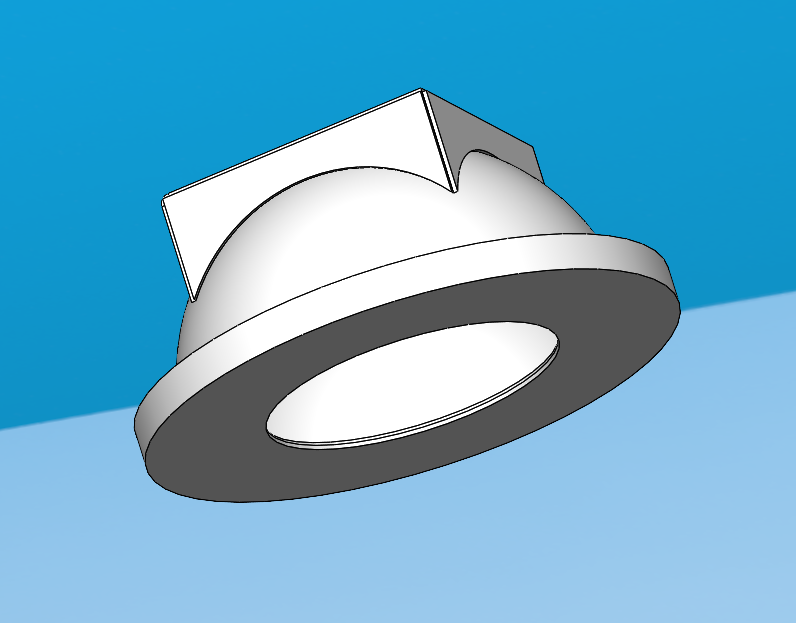

Dimensions: ø144 mm x 60 mm

At Constant Voltage Operation: Have

Diffusor Option: There Are

PRION DOME LIGHT MACHINE VISION IMAGE PROCESSING LIGHT

Dome Light is a specialized illumination source used in industrial image processing systems, providing uniform and shadow-free lighting. Its dome-shaped structure diffuses light from all directions, creating soft and even illumination on the object. This feature minimizes unwanted reflections and shadows on reflective surfaces, ensuring high-contrast and detailed images. It enhances defect detection on metal, glass, and plastic surfaces while reducing shadows on objects with complex geometries.

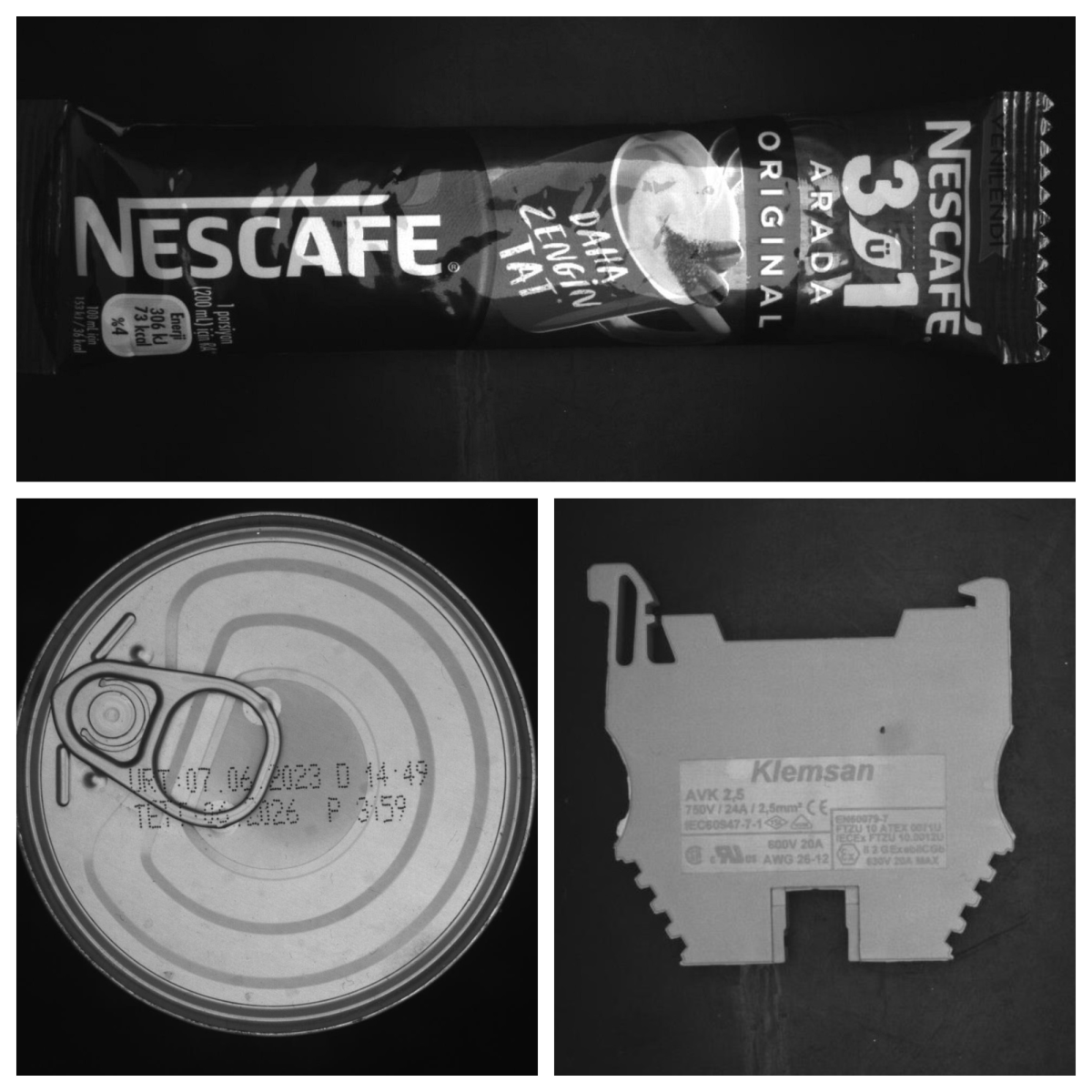

By evenly illuminating texts, logos, and codes, it improves readability and is also ideal for examining the surface details of PCBs and other sensitive components. Providing completely shadow-free and homogeneous lighting, it minimizes reflections on glossy surfaces and enhances details on objects with intricate shapes. By distributing light across a wide area, Dome Light creates a soft and shadow-free image, making it a preferred illumination method for high-precision image processing applications.

Dome Light provides homogeneous illumination while minimizing reflections in machine vision systems, making it an effective solution for imaging shiny, reflective, or irregular surfaces. It is widely used in various applications, including PCB inspection for detecting soldering defects and component placement errors, automotive industry for inspecting reflective metal parts and dashboard panels, glass and plastic manufacturing for identifying scratches and molding defects, packaging and labeling processes for detecting printing errors on glossy surfaces, and the medical and pharmaceutical sector for surface inspection of bottles, ampoules, and blister packs. By distributing light evenly, it eliminates shadows, reduces glare for clearer images, and enhances the detection of complex surface structures. Its versatile application across industries ensures high performance in challenging lighting conditions, improving the accuracy of machine vision systems and enabling reliable inspections.

.png)