Panel Light L212

LUDRE PANEL LIGHT L212 MACHINE VISION IMAGE PROCESSING LIGHT

TECHNICAL SPECIFICATIONS

Illumination Color: 4000K, 6000K, UV 370 nm, UV 390 nm

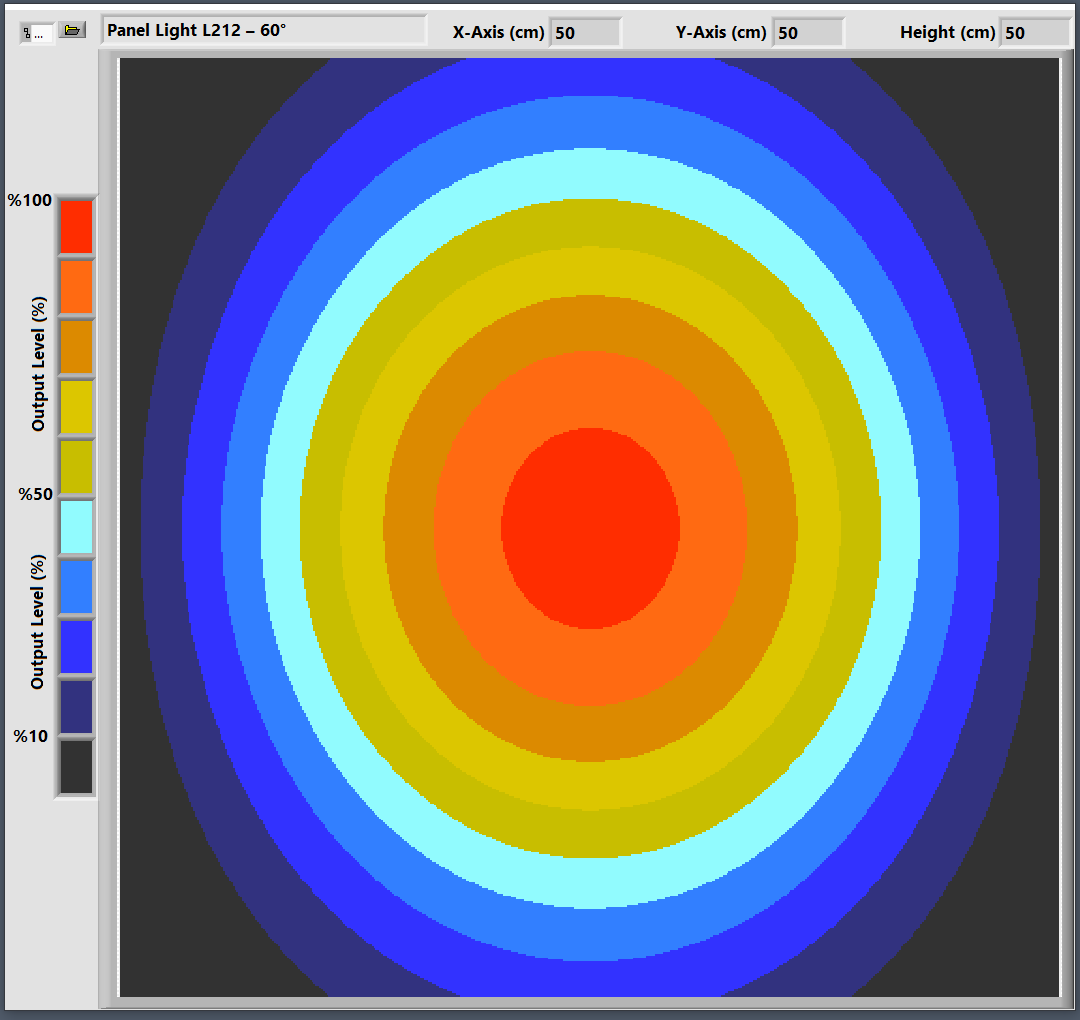

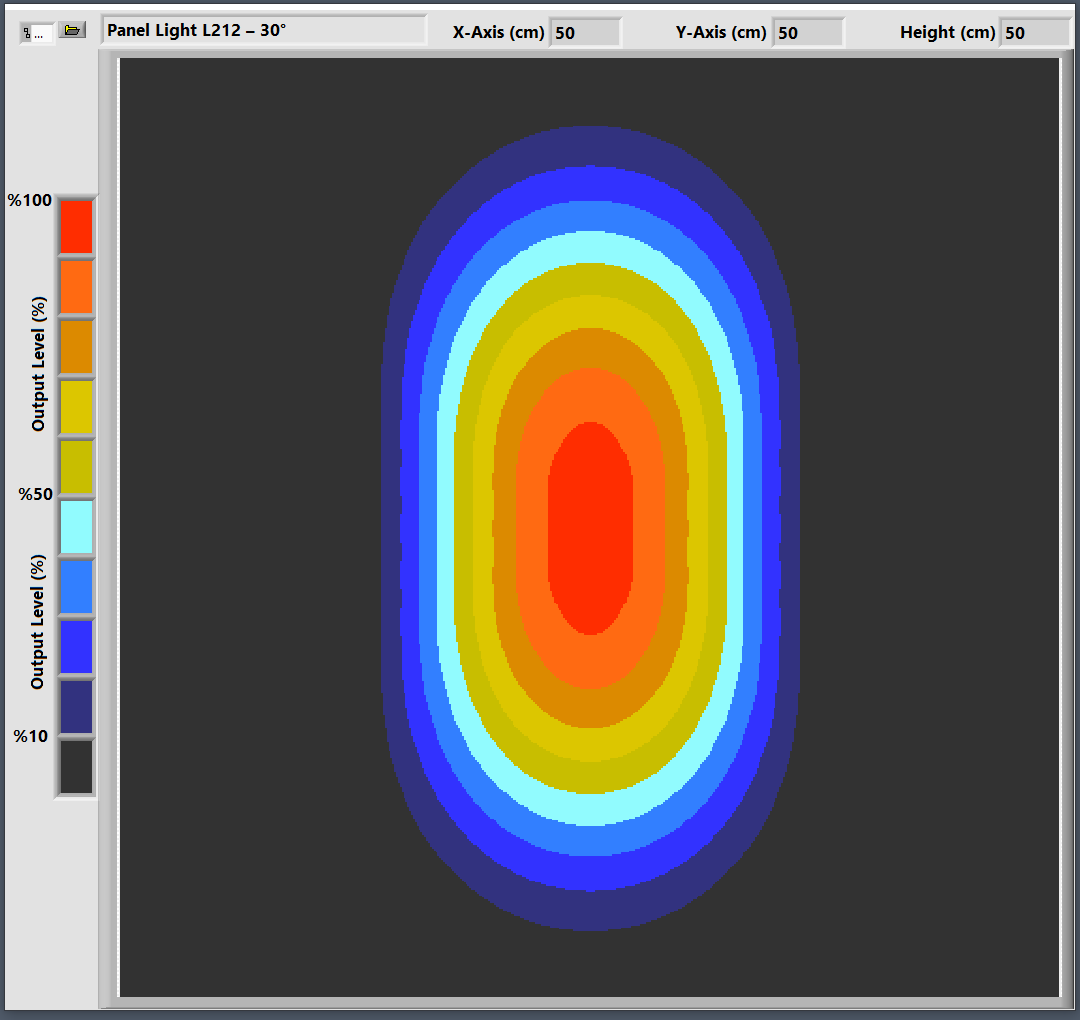

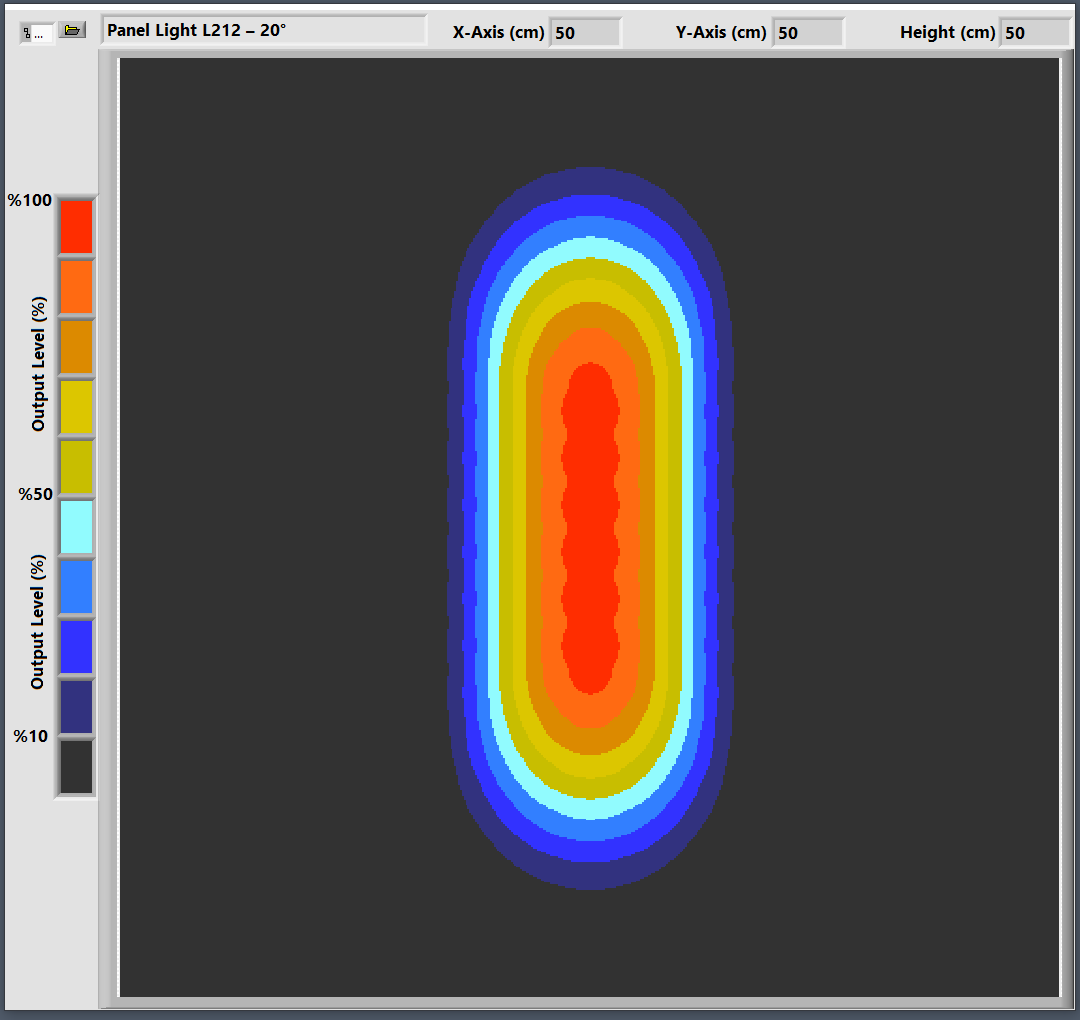

Illumination Angle: 15°, 30°, 60°

Illumination Intensity: 3.84 lm

Number of LEDs: 24

Input Voltage: 24 V

Input Current (15 µs): 4 Amp

Input Current (1 second): 2.8 Amp

Input Current (1 minute): 1.4 Amp

Input Current (continuous): 1 Amp

Dimensions: 33 cm x 75 cm x 2.5 cm

Stable Operation at Fixed Voltage: No

Diffuser Option: No

Bar lighting is a commonly used illumination method in image processing projects. This method involves segments of a linear light source in the form of a bar and offers various features. The following text describes the uses and advantages of bar lighting in image processing projects:

1. Surface Details and Contrast Enhancement: Bar lighting enhances contrast by emphasizing clean surface details. This assists in more detailed analysis by image processing algorithms.

2. Measurement and Dimensional Applications:The linear light source is designed for use in measurements and dimensional applications, allowing for precise measurements.

3. Edge Detection and Contour Extraction: Bar lighting is ideal for edge detection and contour extraction, improving object detection and recognition processes.

4. High-Speed Imaging Applications: Linear light sources are used in high-speed imaging applications to provide clear images of moving objects.

5. Emphasis on Textures:Bar lighting highlights textures on objects, allowing for better focus on material types, patterns, or surface features.

6. High-Precision Reading Applications: Bar lighting is available in high-precision applications such as barcode reading and character recognition. This helps in achieving clearer readings of text and symbols.

7. Shadow Reduction: Proper lighting reduces shadows, ensuring more even illumination of results and enhancing a wide range of image analysis processes.

8. Modular and Compatible Design: Bar lighting systems often have a modular and compatible design, allowing easy adaptation to different application requirements.

Bar lighting, along with the transition timeline, ensures better image quality and analysis results in various image processing projects.

Ultraviolet (UV) illuminations have several significant applications in image processing projects. UV illuminations are commonly found in commercial areas:

1. Fluorescent Substance Detection: UV illuminations are utilized for detecting and emphasizing various details in image processing projects. This is frequently observed in cell analysis and biological treatment applications.

2. Blood Stain and Biological Tracing:UV illumination is employed for the detection of blood stains or biological traces. It is particularly important in forensic science and forensic applications.

3. Analysis of Specific Materials: UV illuminations are used for the analysis and development of specific materials. For example, details of certain chemicals or components are available.

4. Tracking Labels and Stamps: UV light is used for detecting and reading specific tracking labels, stamps, or marks. This is common in industrial production and security applications.

5. UV Fluorescent Paint and Ink Applications: UV fluorescent paints and inks are used in UV illuminations for educational purposes. This is crucial for emphasizing specific features or security characteristics.

6. Determination of Surface Contamination: UV illuminations can be used to determine surface contamination and for cleanliness control. It is particularly effective in quality control ranges in manufacturing environments.

7. Material Inspection in Industry:UV illuminations are used in the inspection of industrial products to determine and examine specific features. This is especially important in applications such as the removal of cracks on metal surfaces.

The use of UV illuminations provides important advantages in specific applications, emphasizing certain features or materials.