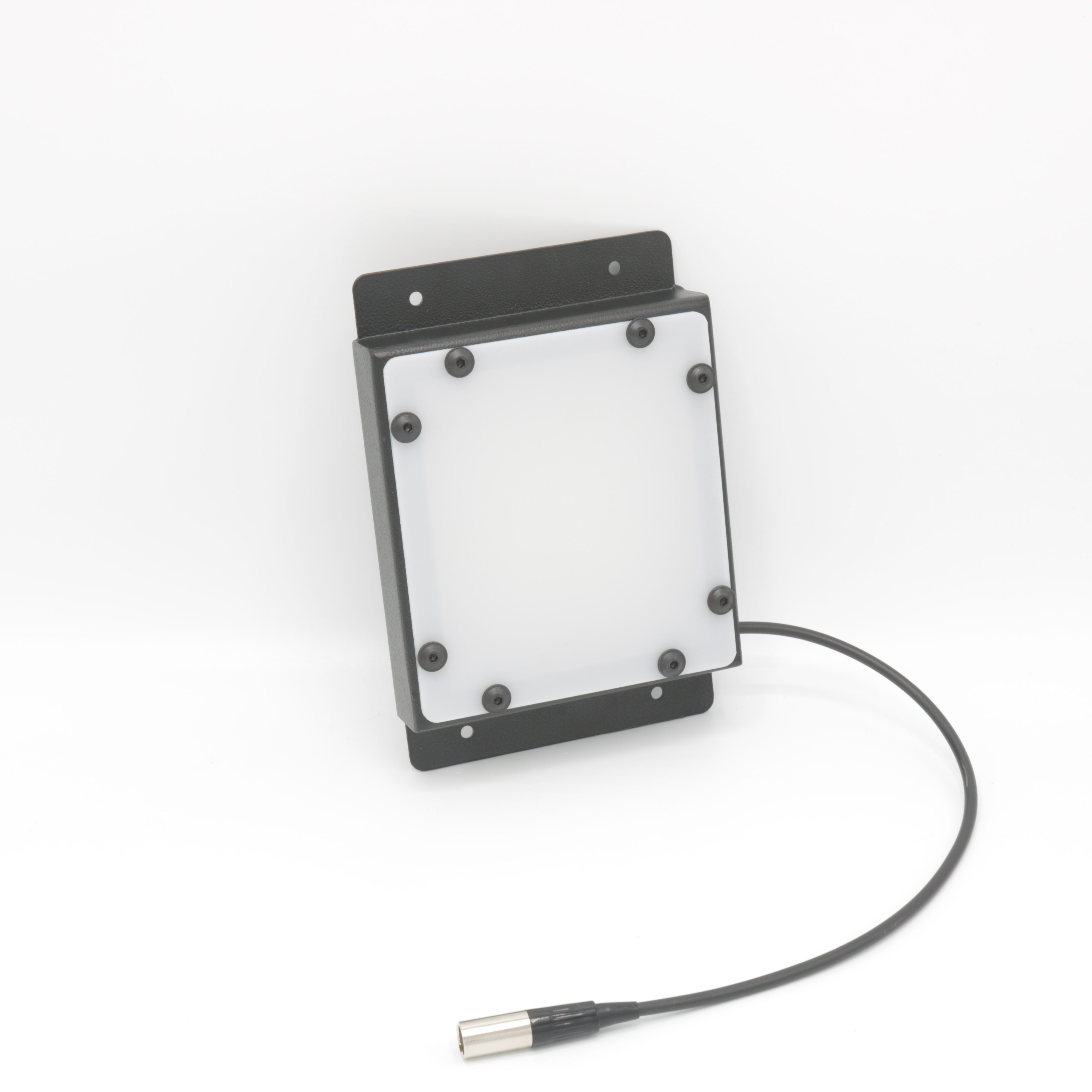

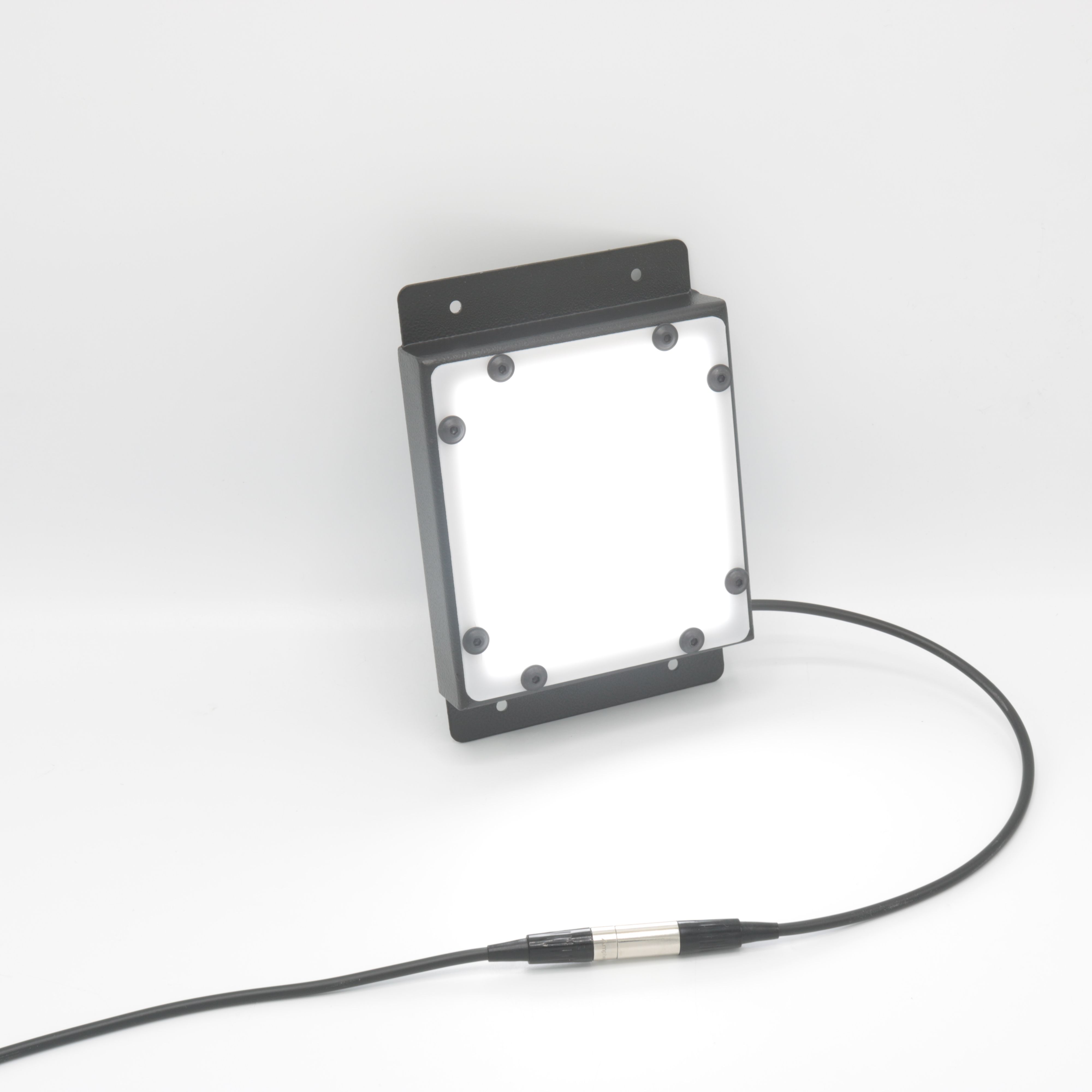

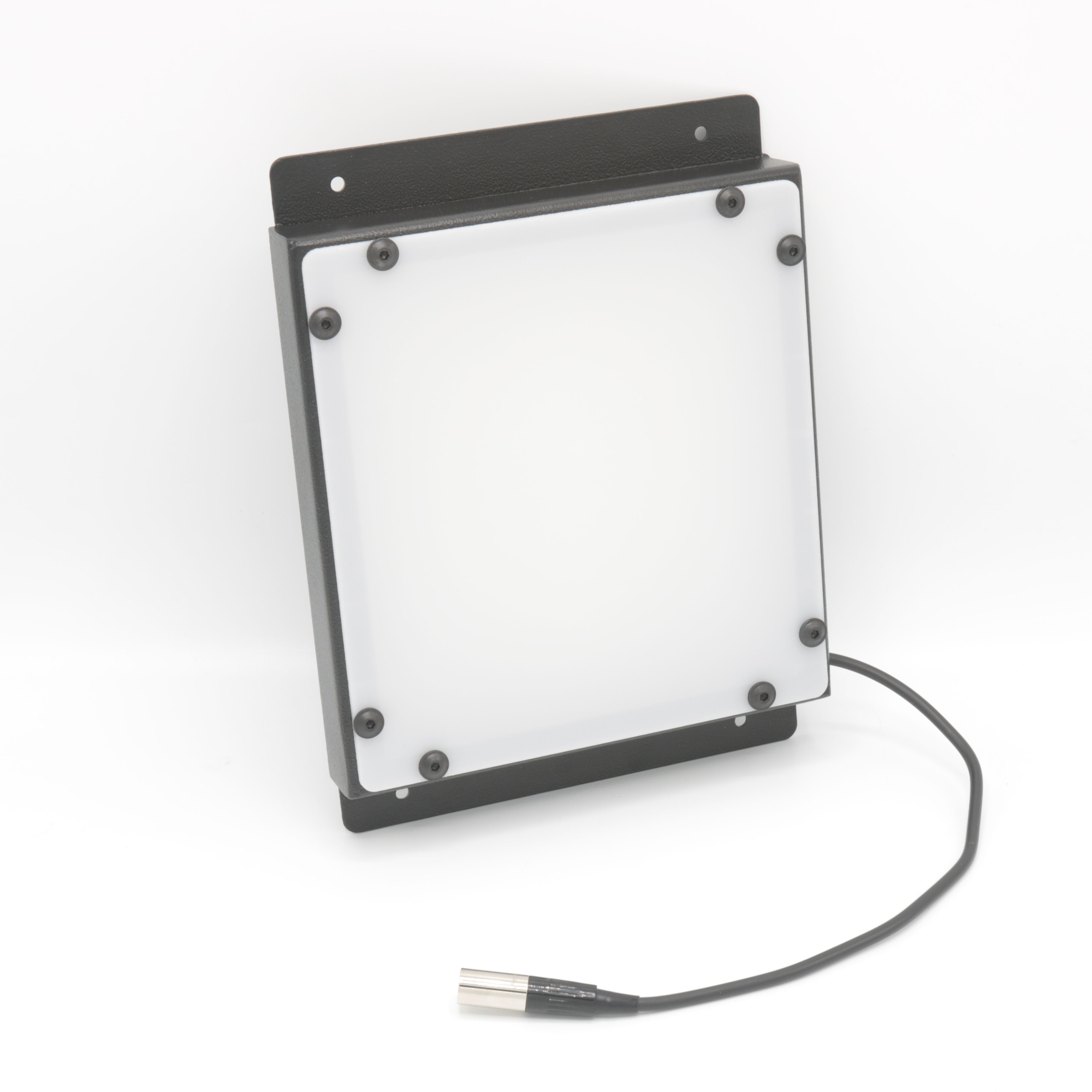

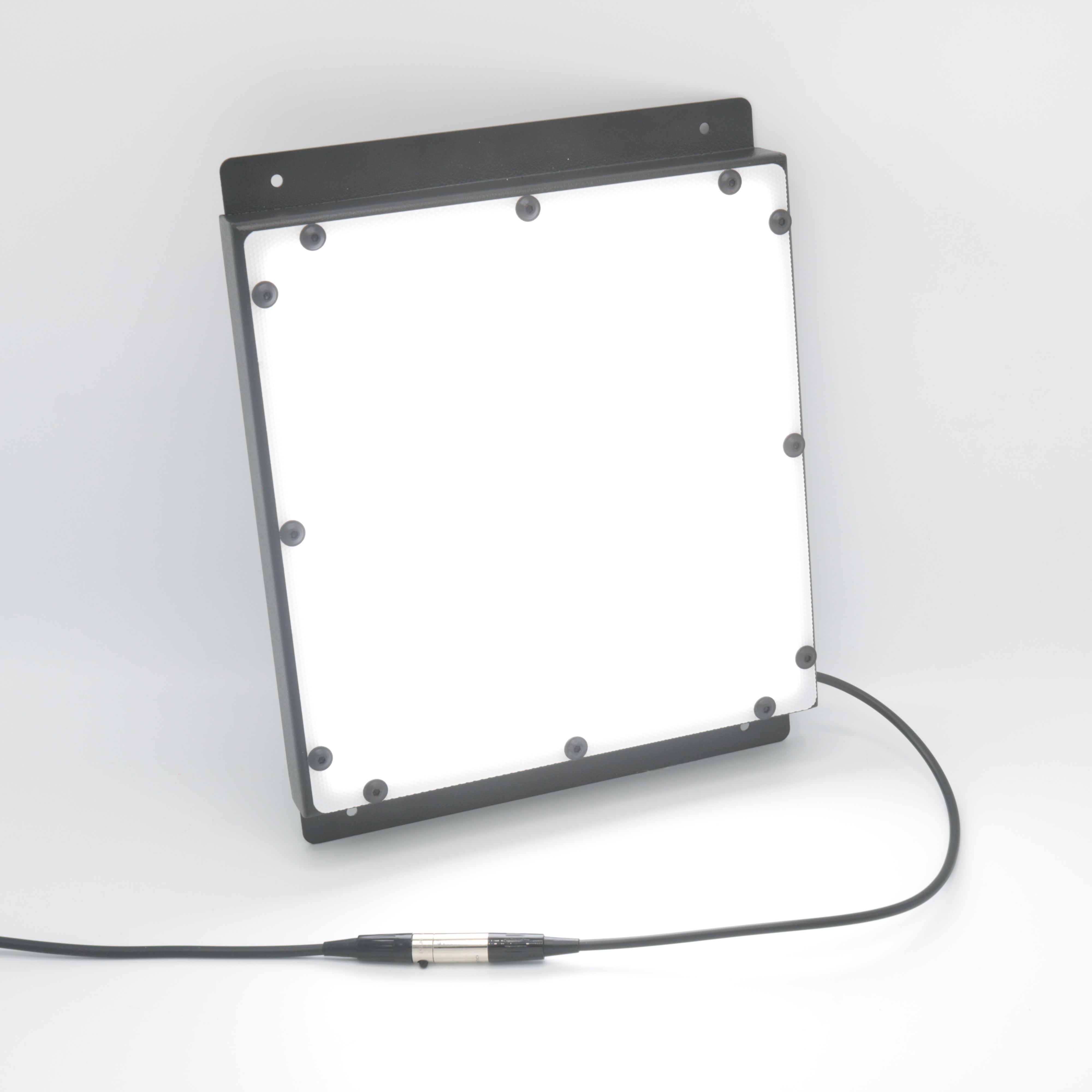

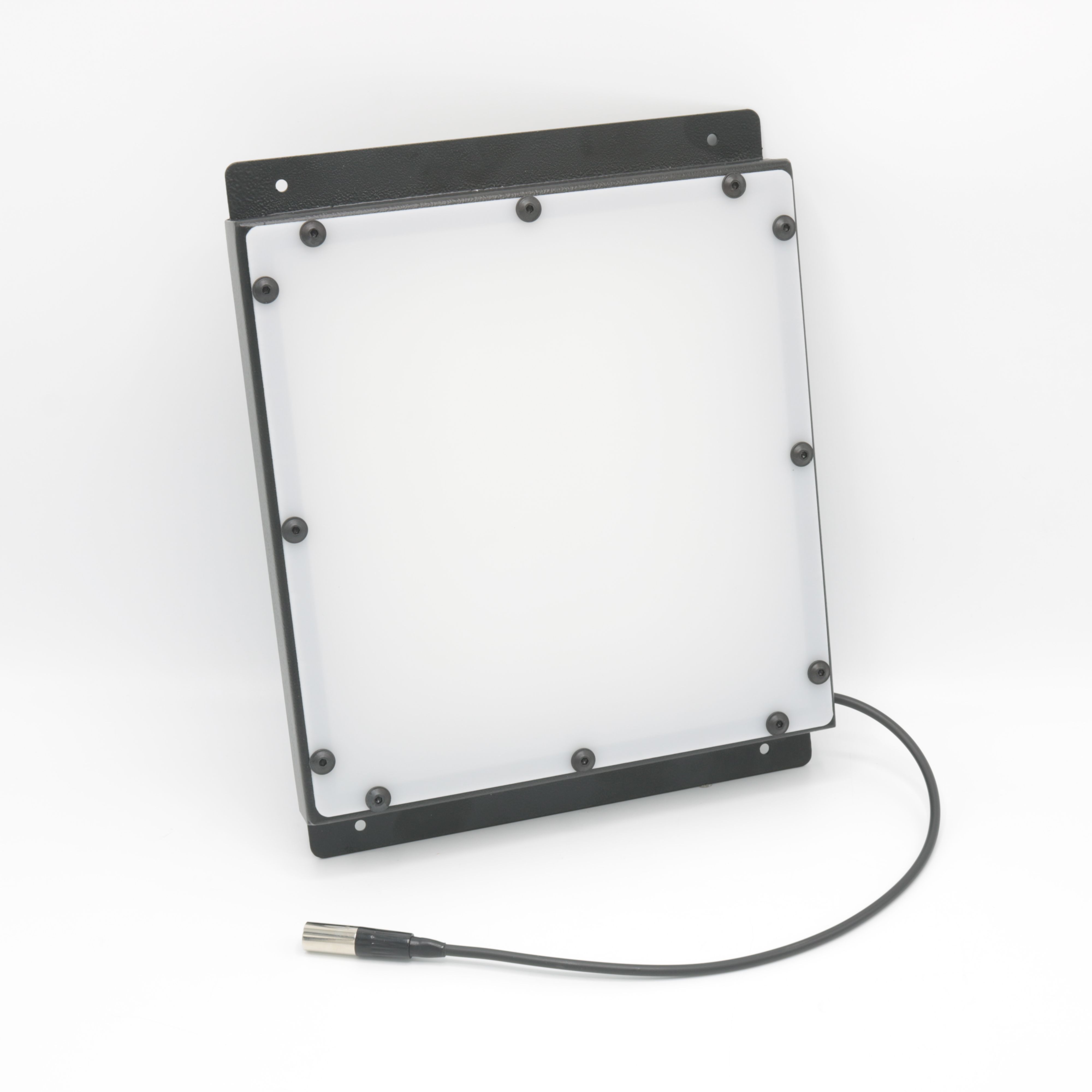

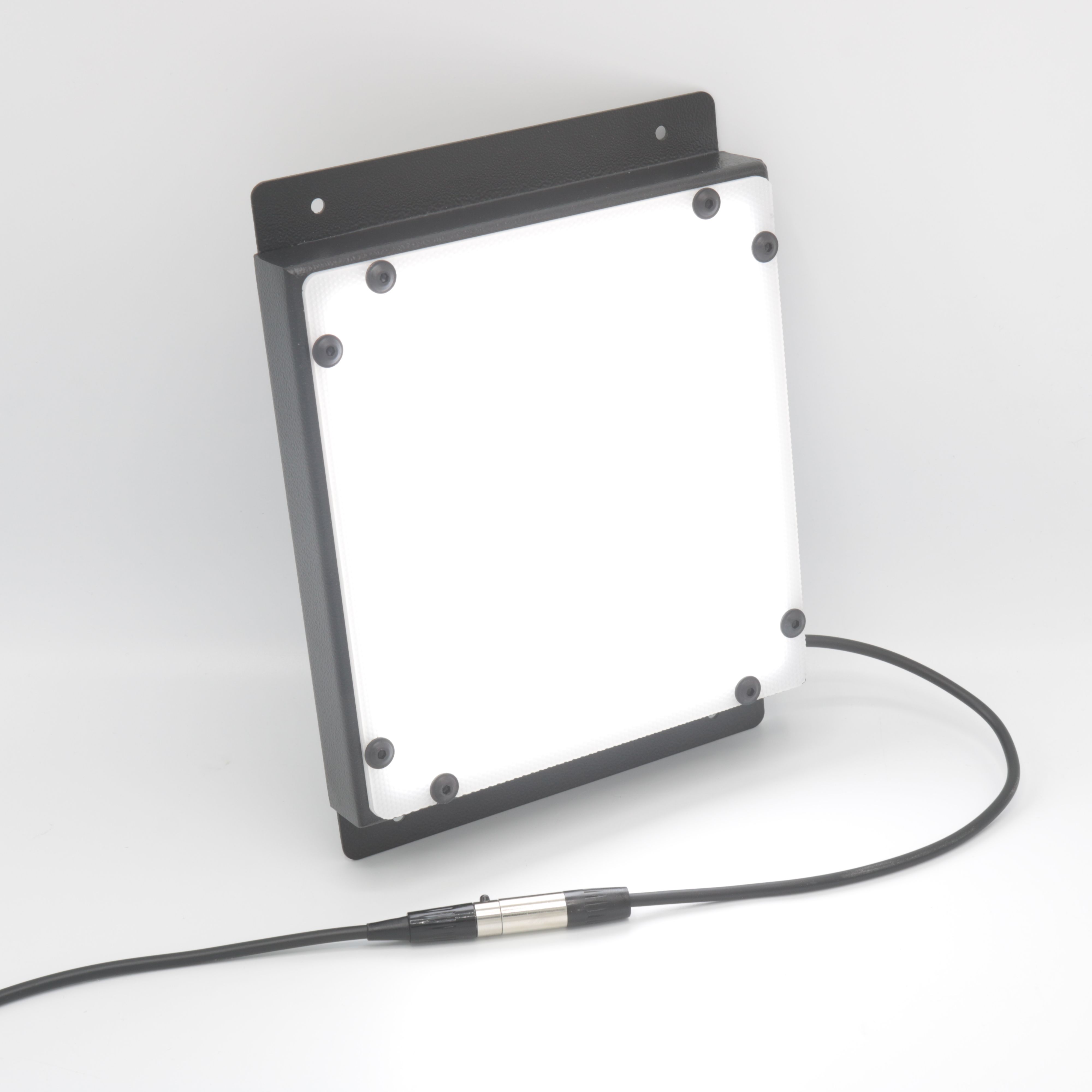

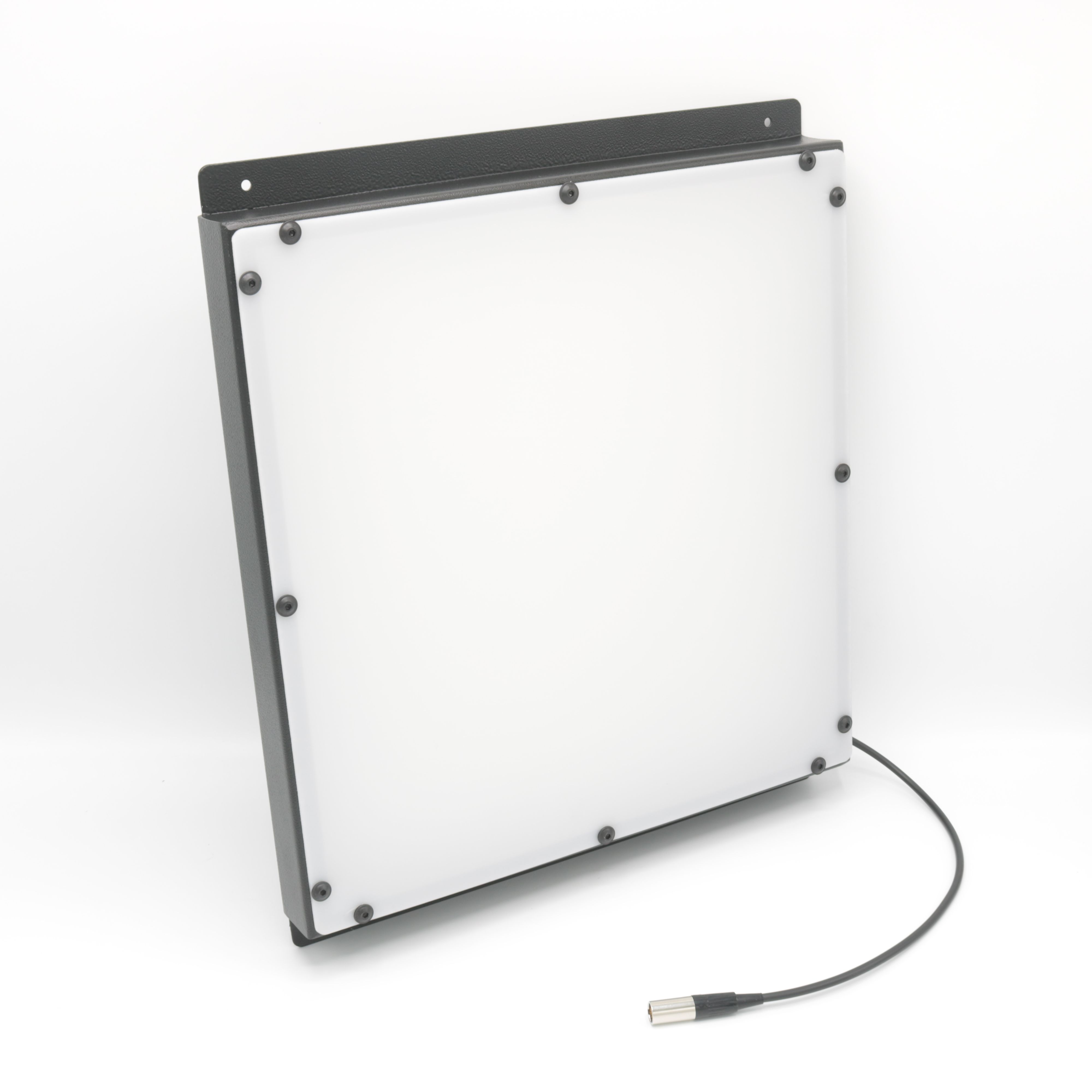

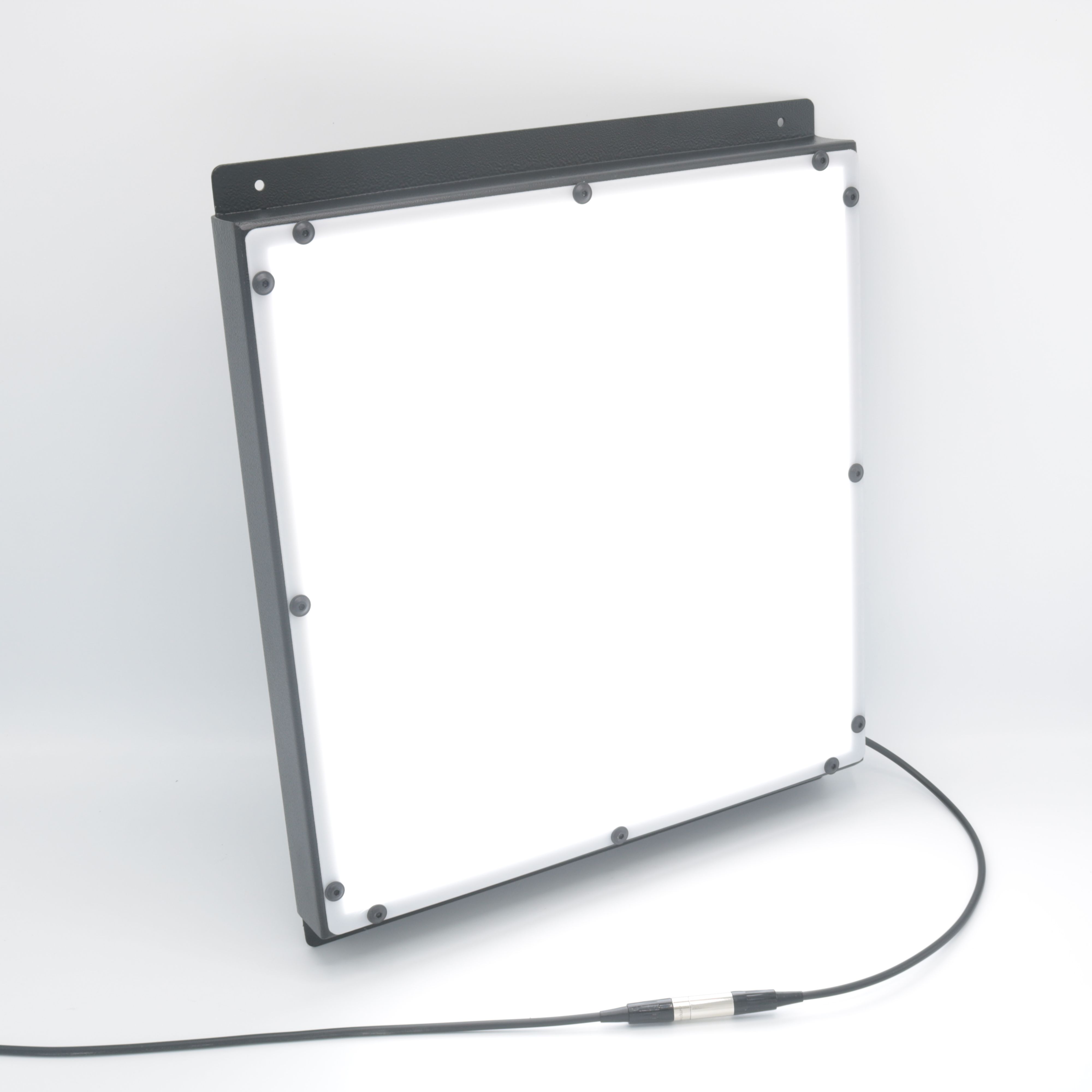

D Series Backlight

| PRODUCT CODE | PRUDUCT SIZE | SUPPLY VOLTAGE | MAX CONTINUOUS CURRENT | PRICE |

| D1010 | 113x163x23 mm | 24V | 0,56 A | 200$ + VAT |

| C1010 | 113x163x23 mm | 24V | 0,56 A | 245$ + VAT |

| D1015 | - | 24V | - | 225$ + VAT |

| D1515 | 163x213x23 mm | 24V | 1,3 A | 300$ + VAT |

| C1515 | 163x213x23 mm | 24V | 1,3 A | 345$ + VAT |

| D1525 | - | 24V | 2 A | 350$ + VAT |

| D2020 | 213x263x23 mm | 24V | 2,4 A | 400$ + VAT |

| C2020 | 213x263x23 mm | 24V | 2,4 A | 445$ + VAT |

| D2030 | - | 24V | - | 450$ + VAT |

| D3030 | 313x363x30mm | 24V | 5,5 A | 600$ + VAT |

| C3030 | 313x363x30mm | 24V | 5,5 A | 645$ + VAT |

| D3045 | - | 24V | - | 675$ + VAT |

| D4040 | - | 24V | - | 800$ + VAT |

| D4060 | - | 24V | - | 900$ + VAT |

| D5035 | - | 24V | - | 925$ + VAT |

| D5050 | 563x510x40mm | 24V | 16 A | 1000$ + VAT |

| D5075 | - | 24V | - | 1125$ + VAT |

| D8080 | 813x863x50mm | 24V | 40,9 A | 1600$ + VAT |

Machine Vision and Image Processing Lighting Back Light

Backlight is a critical lighting solution, especially in image processing and computer vision applications. In industrial imaging systems, backlighting is used to clearly distinguish the contours, edges, and details of objects. This technology is often preferred in high-precision computer vision systems and offers significant advantages in applications such as quality control, defect detection, and measurement.

Backlighting enables objects to create a silhouette by allowing light to pass through or around them, rather than being directly observed by a camera. This method enhances the sharp contrast around objects, making it easier to separate them from the background. As a result, the dimensions, positions, and shapes of objects can be detected with high accuracy.

Image processing algorithms can perform tasks such as object detection, classification, and defect analysis more efficiently with the help of backlighting. Additionally, providing high-quality data is crucial for deep learning models used in computer vision systems to produce accurate results. Backlight plays a key role in ensuring this data quality.

Backlighting also excels in challenging tasks such as barcode recognition, precise hole measurement, edge detection, and micro-detail analysis. These applications are especially important in automation systems, robotic production lines, and advanced technologies like medical imaging.

In summary, backlight illumination is an indispensable element for increasing both the accuracy and efficiency of image processing and computer vision applications. Choosing the right type of lighting is one of the key factors that directly impacts the success of a high-performance computer vision system.

.png)

Back Light illuminations play a critical role in image processing applications as specialized lighting systems. These illuminations are particularly used in inspection processes requiring high contrast, helping to highlight the contours of objects and reveal details of transparent or semi-transparent materials.

In image processing systems, back light is typically placed behind the product to clearly detect the silhouette of the object. This method offers significant advantages in industrial processes such as measurement applications, defect detection, shape analysis, and quality control. The use of back light is especially beneficial in the inspection of glass, plastic, and thin metal parts, allowing operators and automated systems to quickly and accurately detect defects.

Back light illuminations are extensively used in various industries due to their ability to enhance visual inspection and quality control. In the glass industry, back light is essential for detecting cracks, scratches, and structural defects in glass panels and bottles. In the automotive sector, it is widely used for measuring parts, analyzing component integrity, and inspecting headlamp lenses. The electronics industry relies on back light for PCB component placement verification and microchip inspections. In the textile industry, back light helps in detecting fabric defects such as tears, stains, and inconsistencies in material texture. Additionally, the food and pharmaceutical industries utilize back light for packaging inspections, filling level control, and ensuring product integrity.

Back light solutions designed specifically for image processing systems provide uniform light distribution, ensuring consistent and reliable results. LED-based back light systems offer cost advantages in industrial applications due to their long lifespan and low energy consumption. Moreover, when used with strobe drivers, the light intensity and timing can be optimized, enabling image processing with much higher precision.

In conclusion, back light illuminations are indispensable components for numerous applications requiring precision and accuracy in image processing. With extensive use in quality control, measurement, defect detection, and automated inspection systems across industries such as glass, automotive, electronics, textile, food, and pharmaceuticals, back light solutions enhance the efficiency and reliability of industrial production processes.

.png)

.png)